feature

HU-BRAIN’s Strengths

More advanced image processing technology

Hu-Brain’s image processing software (Hu-Dra), developed in-house, is an ever-evolving technology that can respond quickly and meticulously to customer requirements.

1.Each time the inspection is performed, the contour of the object is captured, following which the inspection window is reduced in size so that (as shown in Fig A), the black area can be accurately inspected regardless of differing line widths.

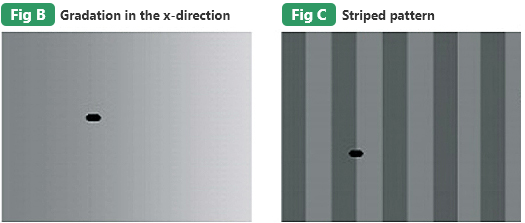

2.An inspection logic (shift subtraction method) is used to respond to variations in brightness and illuminance gradients, enabling the detection of black spots even in cases such as those shown in Fig B and C.

3.The information required for production (ID number, serial number, etc.) is added and displayed.

Responding to customer needs with completely custom-made products tailored to manufactured goods and applications

At HU-BRAIN, we handle the entire product process end-to-end, including designing, manufacturing, and post-delivery start-up of image inspection equipment.

Different industries use different inspection methods depending on the products.

In addition to planar inspection, we offer completely tailor-made products for cylindrical, spherical, or complex shapes in combination with the most suitable transportation equipment. Tailor-made development allows us to meet detailed needs that cannot be met by mass-produced products. We will deliver the best AOI system for your requirements.

Adaptability enabling us to cover all manufacturing industries and high-speed and high-precision robot technology

Product inspection is essential in every industry.

HU-BRAIN can provide the inspection needed by all types of manufacturing industries, including electronic components, semiconductors, automotive components, food containers, medical devices, batteries and energy.

In addition to automating the inspection process, which used to be done manually, we have also achieved high speed and high precision, including fast and accurate movement of the object to be inspected. By making full use of robots, HU-BRAIN’s image inspection equipment boasts a high degree of precision that enables it to meet the strict quality control requirements for electronic and other components installed in automobiles.

products

Products

We develop tailor-made image inspection equipment that automates various processes related to quality assurance for manufacturing in all types of industries.

cases

Examples of Products in Use

We have continually advanced our image processing and automated transportation technologies to provide optimal solutions tailor-made to meet every customer request. Here are some of the examples.

company

Company Profile

Please click here to find out about HU-BRAIN’s corporate concept, CEO’s message, how to find us, etc.