3D inspection system with high speed and high resolution

Features

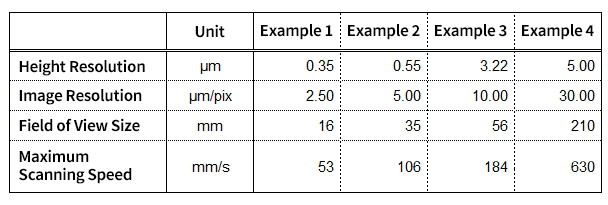

- Cameras can be selected from a varied lineup according to the application of the inspection. (Example) 0.55–5.0 μm height resolution, and 5–30 μm/pixel horizontal resolution

- Example of 3D variation: 106 mm/s scanning speed was achieved at 0.55 μm height resolution, 5 μm horizontal resolution, and 35 mm visual field size.

- Color image inspection is also simultaneously performed using our original image inspection software, based on the 2D color image data captured at the same time as the 3D image data.

- In this product, created through collaboration with Linx Corporation, 3D and 2D inspection equipment has been incorporated into transportation equipment that has been tailored to customer specifications, and systematized at our own factory.

Overview

■3D measurement with high precision and high resolution

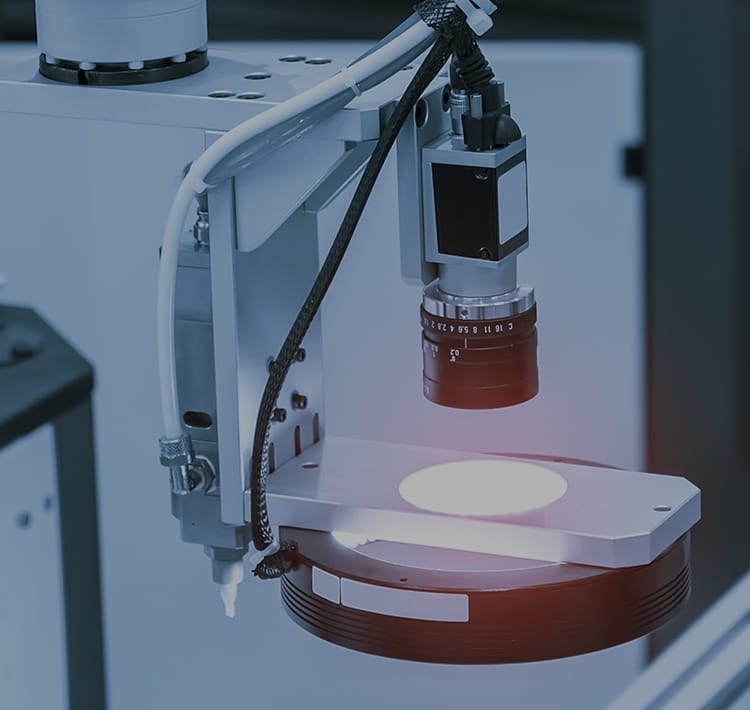

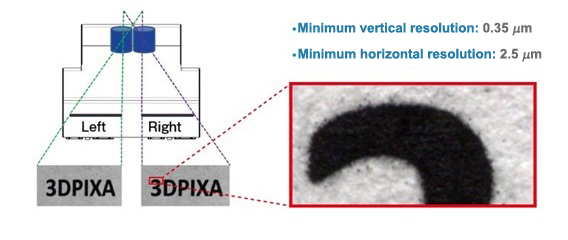

- Stereo-method line scan camera

- Uses the high resolution of the line sensors to capture micro-textures and reconstruct shapes

- Minimum height measurements of 5 µm horizontally and 0.35 µm vertically

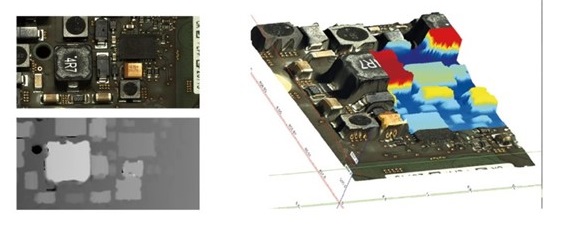

■3D data and color images

- Simultaneously acquires full color and height images in one scan

- Achieves advanced inspection, combining shape information and 2D information in full color

■Examples of applications of 3D inspection

Ceramic circuit boards: Pattern film thickness, slight unevenness, via depth, circuit board warpage, and height of adhered foreign matter

BGA bumps: Height, diameter, and coplanarity

Connectors: Flatness of terminals and shrinking of resin parts

Lead frames: Coplanarity of inner leads

Others: Scratches on the surfaces of films/glasses/resin moldings/press moldings/cast products, and slight unevenness

Semiconductors: Disbonding from wire bonding/bond pads; height abnormalities, etc.

■Examples of camera specifications

Specifications

| Software | Multifunctional image processing software Hu-Dra |

|---|---|

| Cameras | 3DPIXA |

| Equipment size | 1,000 (W) x 1,300 (D) x 1,800 (H) mm (excluding rotating warning light and HEPA) |