Free-angle visual inspection equipment for multiple surfaces

Features

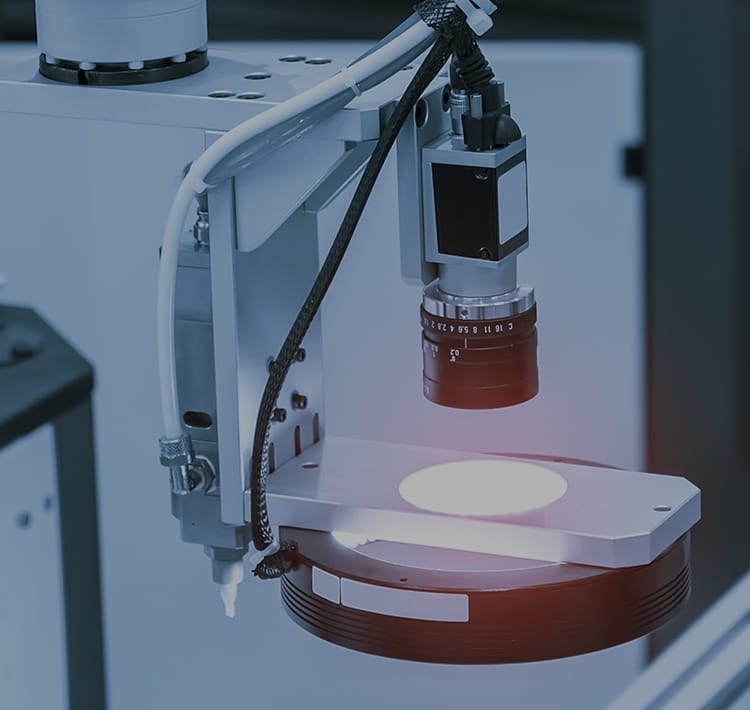

- Uses our original image processing software Hu-Dra. Products are suctioned and transported from the tray, and the images are captured by camera and processed.

- Expected product size ranges from 5 to 50 mm.

- Multiple optical systems allow detection of various non-conforming points.

- Supply section is also compatible with workpieces in loose state.

- Recommended for small-quantity/large-variety products.

Overview

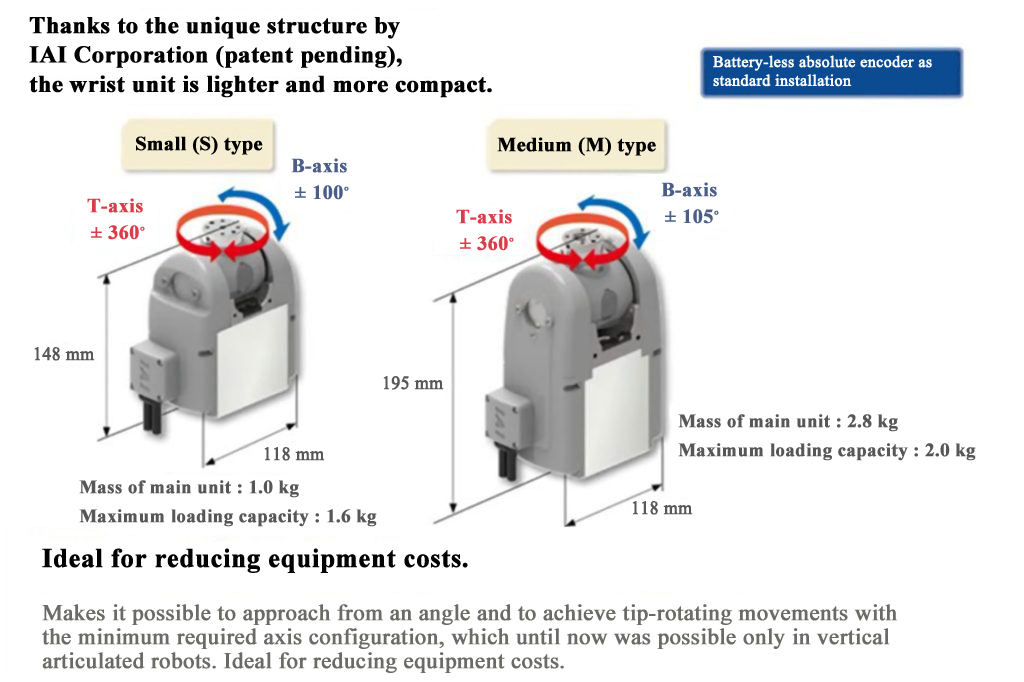

■Features of the hand unit

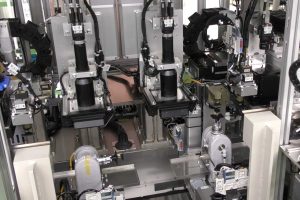

■Device Overview

Visual inspection of modules and lead-attached products, mimicking human observation.

Capable of handling multiple sizes with simple setup changes.

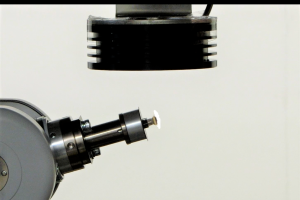

- Angled approaches by the robotic hand allow inspections from all angles, including sides and edges.

- Hybrid image processing, combining our original image processing software with artificial intelligence, allows more reliable detection. It is equipped with functions which inspect every corner as if seen by human eyes.

- Changing the suction mechanism at the end of the hand enables multiple types and workpiece sizes to be handled simultaneously.

- Compatible with automatic inspections equipped with loader and unloader.

■Target Products (Examples)

High-frequency communication components, optical communication components, ceramic packages, cutting tools, carbide tools, and machining tips

Specifications

| Software | Multifunctional image inspection software HU-3120 Hu-Dra specifications |

|---|---|

| Cameras | 25-megapixel color camera (for inspection) and 5-megapixel color camera (for alignment) Equipment size: Approx. 2,650 (W) x 1,400 (D) x 1,800 (H) mm (signal tower not included) |

| Equipment size | Approx. 2,650 (W) x 1,400 (D) x 1,800 (H) mm (signal tower not included) |

| Mass | Approx. 1,000 kg |

| Workpiece Size | 5–50 mm (reference value) *This depends on thickness, material, and mass of sample. Please contact us for details. |