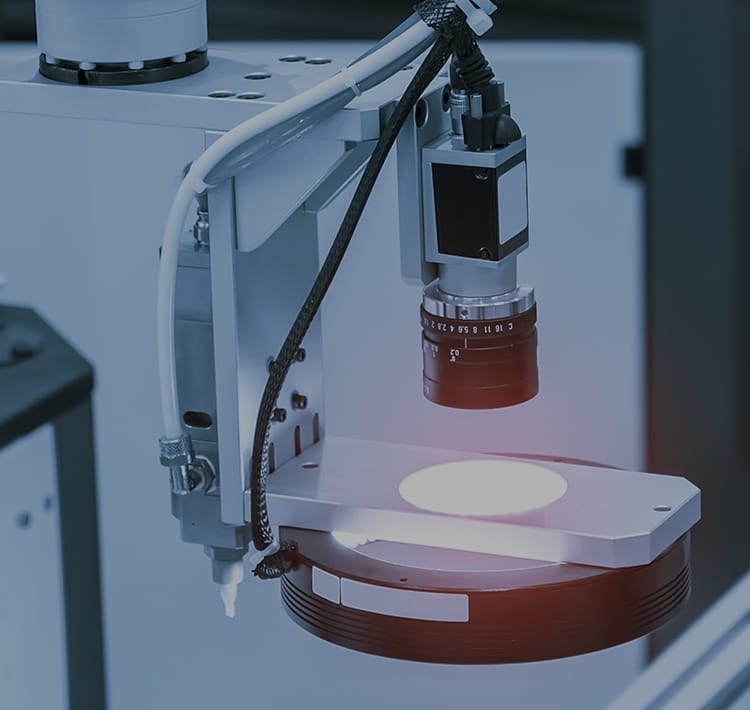

Inspection equipment for high-speed inspection of entire surface of cylindrical components

Features

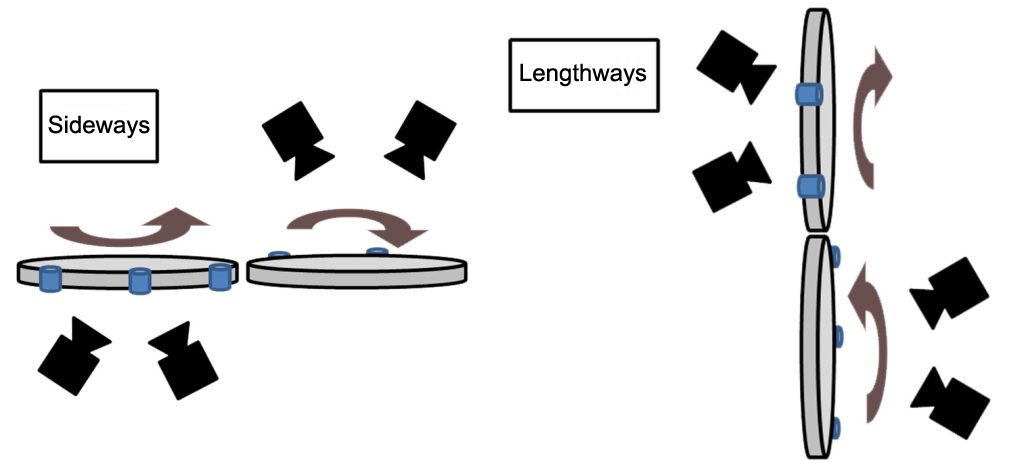

- The images of the entire surface of cylindrical workpieces are inspected at high speed.

- The shapes of the side (circumferential) and front/rear surfaces are inspected.

- It can also be used with high-resolution cameras to reliably inspect even the smallest scratches.

- A certain number of images for non-conforming workpieces can be stored as history, which is convenient for later analysis.

- The type registration function allows for easy changeover between different workpiece types and inspection of multiple workpieces.

- It has been widely used with metals, ceramics, resins, etc..

Overview

Specifications

| Software | Multifunctional image inspection software Hu-Dra |

|---|---|

| Cameras | 2-megapixel color camera |

| Number of Cameras | [Example] 10 units (8 units at side surfaces, 2 units at end surfaces) |

| Processing Speed | [Example] About 500 pieces/min (varies with pin size, shape, mass, etc.) |

| Control input/output | I/O Check 16-bit, open collector output |

| Power source | AC200 V single phase, 3 A |

| Others | Lenses and lighting should be selected according to the workpiece and inspection contents. |