Inspection system for exterior prints on containers

Features

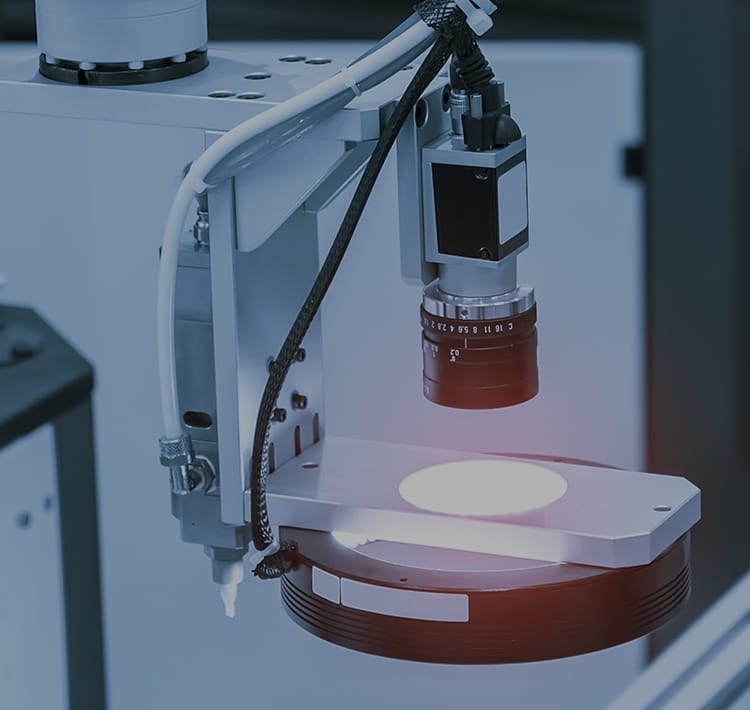

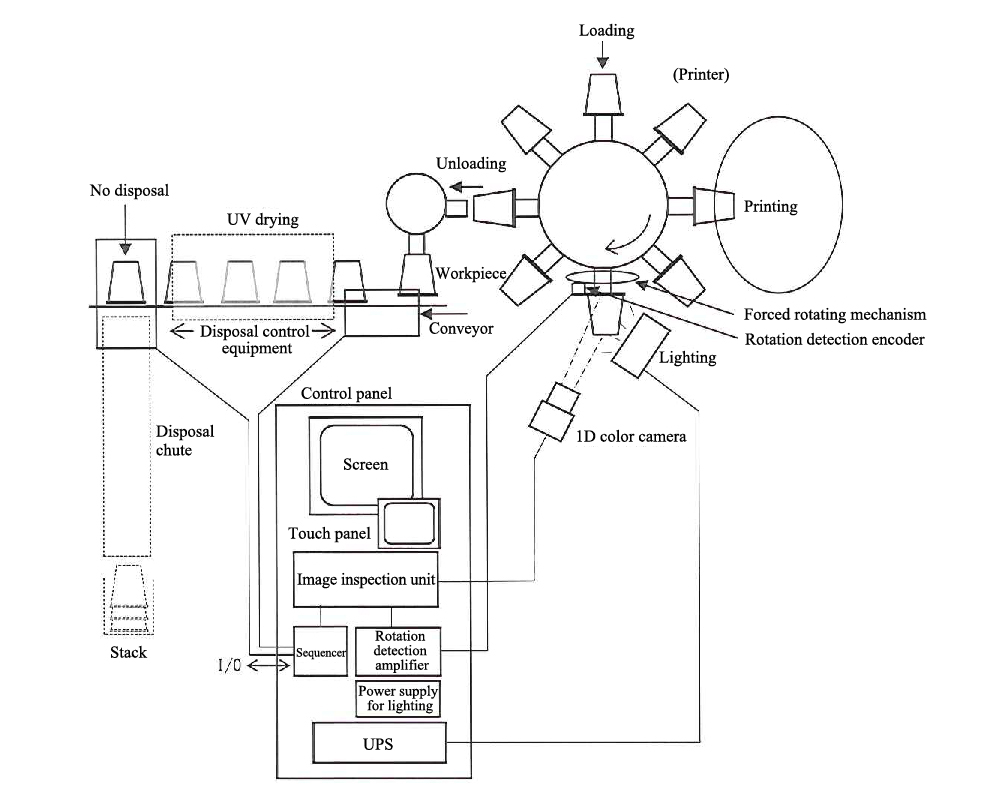

- This system detects any print omissions or dirt contamination on the exteriors of cylindrical workpieces such as cup noodle containers by image inspection.

- As the workpiece rotates on its own fixed axis, images are captured and assessed by a color 1D camera.

- It conducts high-precision inspections, tracking any distortions or misalignments in the print.

- In addition to print inspection, it can also use different logics to detect burring and inspect for chipped flanges by using different logics.

- Detected non-conforming areas are indicated by a square-framed mark.

- Up to 10 images for non-conforming workpieces can be stored, and inspection can continue while these images are displayed.

- The type registration function allows for easy changeover between different workpiece types.

Overview

Specifications

| Software | Multifunctional image inspection software Hu-Dra |

|---|---|

| Screen | 17-inch LCD display |

| Cameras | 1024-pixel color 1D CCD camera with 3-line system and exposure control function |

| Image resolution | 640 pixels (vertical) x 960 pixels (horizontal in rotation direction) |

| Processing Speed | 300 pieces/min (please contact us if higher speed is required) |

| Control input/output | I/O 32-bit, open collector output |

| Power source | AC100 V, 5 A |

| Optional accessories | Forced rotating mechanism and discharge mechanism |

| Others | Lenses, lighting, mechanisms, and controls must be designed and selected according to the shapes of the workpieces and the equipment. |