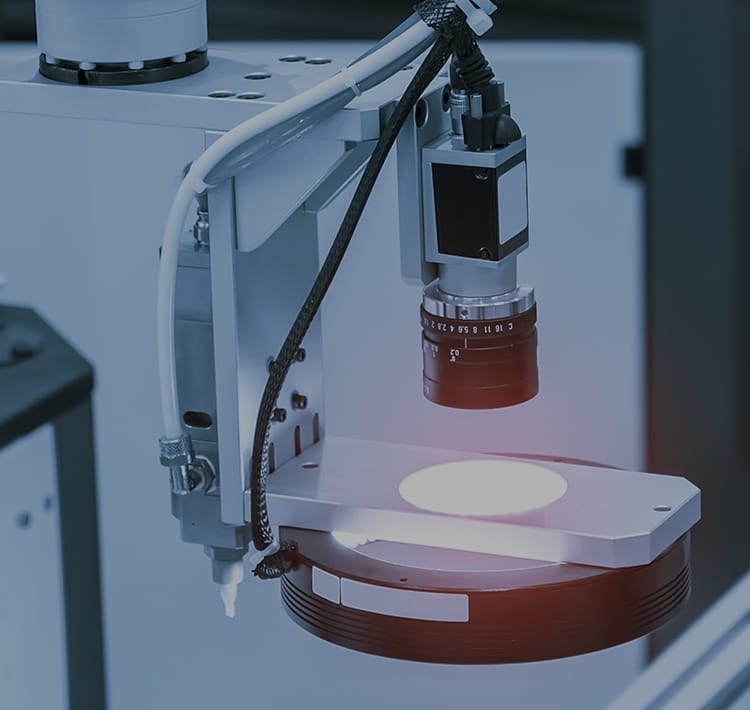

Inspection system for inner surfaces of containers

Features

- The inner surfaces of containers, such as paper cups, are inspected for black spots and dirt contamination.

- Various inspection logics can be selected and set up as desired for each inspection point.

- Detected non-conforming areas are marked with a square-framed mark, while an enlarged image of the area is also displayed.

- The most recent history for the enlarged images for non-conforming parts (up to 12) is displayed on the screen.

- The laminated area is automatically detected and masked, while separate processing is carried out, resulting in the entire surface being inspected at a high precision level.

- The type registration function allows for easy changeover and inspection of workpieces with different shapes and conditions.

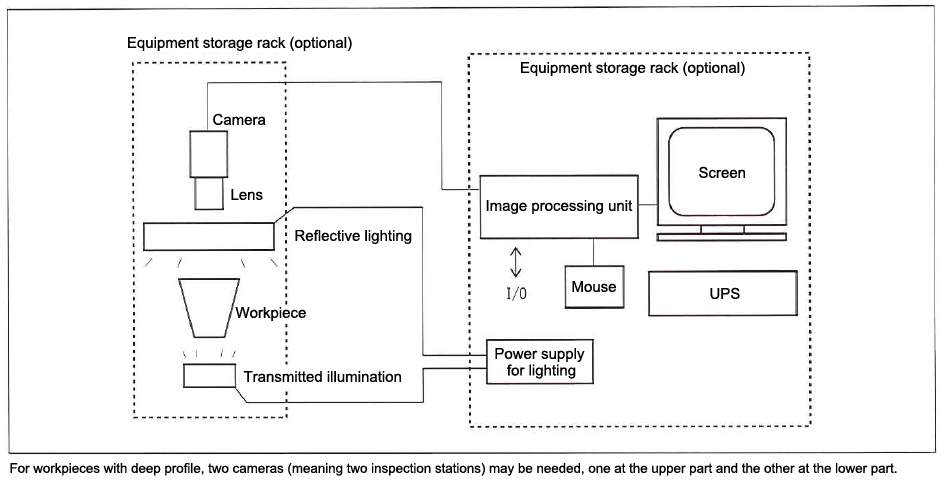

Overview

Specifications

| Software | Multifunctional image inspection software Hu-Dra |

|---|---|

| Cameras | 1.45-megapixel monochromatic double-speed camera with progressive scan and random trigger shutter functions |

| Processing Speed | 200 pieces/min (please contact us if higher speed is required) |

| Output result | I/O 8-bit, open collector signal |

| Power source | AC100 V, 6 A |

| Options | Image input and discharge control devices |

| Others | Lenses and lighting should be selected according to the workpiece and inspection contents. |