Visual inspection equipment for communication/high-frequency components and device modules

Features

- A structure with a flexible design that enables imaging from the optimum angle to detect non-conforming items in optical, wireless communication, and high-frequency components, devices, and modules for which visual inspections are difficult due to their complex shapes.

- Compatible with products of various shapes, thanks to our optical engineering capabilities cultivated over 34 years as a specialized manufacturer of visual inspection equipment and our advanced image processing technology developed in-house.

- Using options, it is possible to build a production management system as part of Internet of Things, including information communication with a host server, feedback to the front-end process, and large-volume storage of inspection results.

- Through installation of a remote system, the image inspection software in the equipment can be edited directly from a remote location. For programmable logic controller (PLC) software debugging work, we remotely check the ladder logic in real time and identify the defective parts.

Overview

■Examples from our production track record

Tray-to-tray free angle inspection equipment

- Equipped with loader/unloader

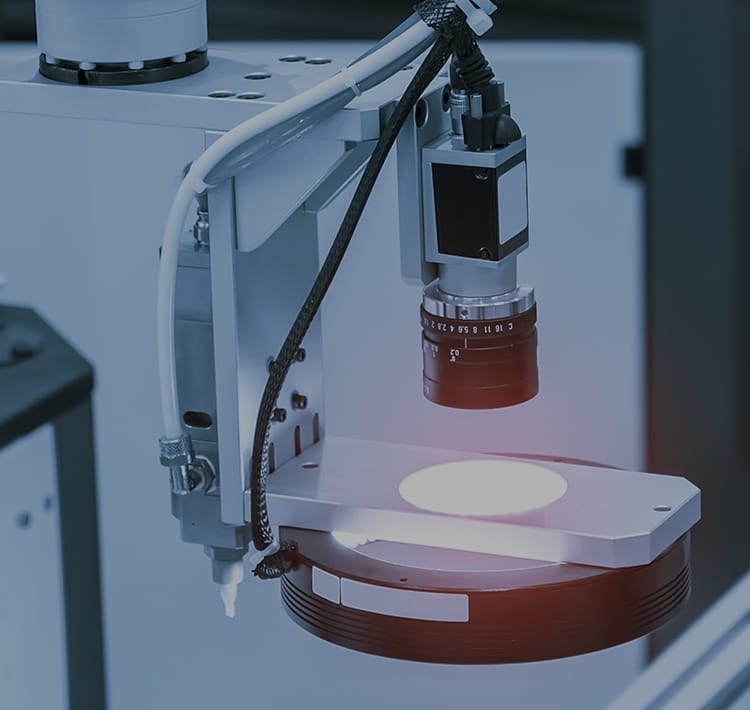

- The free-angle unit adheres to the workpieces, and images are captured from an optimal angle for detection without any blind spots

- Only conforming products are packed in trays and stored in magazines

Inspection equipment for index method communication components/modules

- Removes workpieces from trays and transports them to index table

- Captures images from any desired angle while aligning

- Equipped with unique autofocus function

■Inspection items

Scratches, bent components, misaligned installed components, adhesive resin defects, discoloration, unevenness, etc.

Three dimensional (3D) inspection equipment can be incorporated.

■Workpieces for inspection

Optical communication components, high-frequency communication components/devices/modules, etc.

Specifications

| Software | Multifunctional image inspection software Hu-Dra |

|---|---|

| Cameras | 5-megapixel camera, 25-megapixel camera (color/monochromatic) |

| Lighting | φ100 dome lighting and coaxial lighting |

| Others | *Lenses and lighting models should be selected according to the shape of the workpiece. *Inspection precision depends on the shape of the workpiece. This will be confirmed upon sample evaluation. |