Visual inspection equipment for trays

Features

- An XY-axis robot scans the camera; each workpiece arranged on trays is continuously inspected individually at high speed.

- A parallel arrangement of color cameras and high-pixel monochromatic cameras. Even small scratches and stains are reliably detected.

- After image inspection of all workpieces, non-conforming workpieces are discharged from the tray, and the tray is automatically refilled with conforming workpieces.

- Up to 100 types can be set.

- Compatible with circuit board type products.

Overview

■Functions

- Two cameras (a color camera and high-pixel monochromatic camera) are used to perform continuous inspection of electronic components packed in trays at high speed; non-conforming workpieces are discharged, while trays are automatically refilled with conforming workpieces.

- As the images are processed using the software developed in-house for electronic components, inspections can be tailored to customers’ needs.

■Inspection items

Cracks, chips, scratches, stains, cracks, foreign matter adhesion, unevenness, and lamination misalignment

Pattern chipping and deformation

■Inspection capacity

- Image processing time: 100 msec/piece

- Resolution: 5 μm/dot

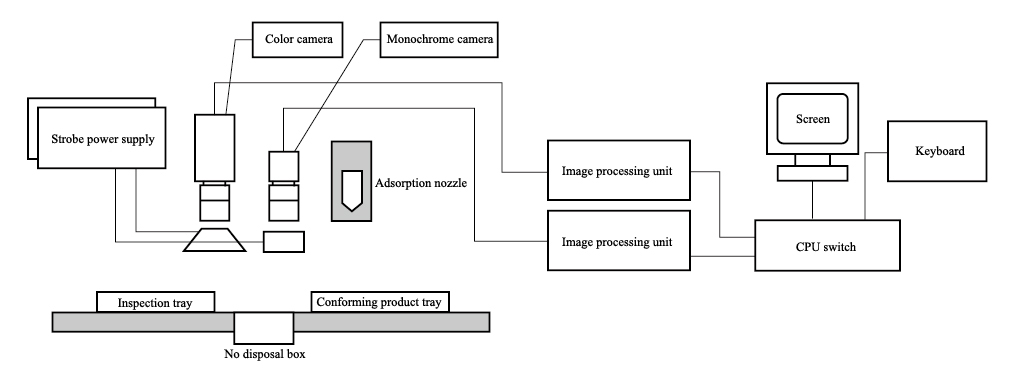

■System Configuration Diagram

Specifications

| Cameras | One 2-megapixel color area camera *Can be modified to max. 25-megapixel One 2-megapixel monochromatic area camera |

|---|---|

| Inspection method | Using a two-axis control robot, the images of the tray-packed electronic components are continuously captured with two cameras. |

| Dimensions | 1,000 (W) × 950 (D) × 2,100 (H) mm |

| Mass | Approx. 300 kg |

| Power source | AC200 V ± 10% 50/60 Hz 1.5 kVA |

| Air Source | 0.5 MPa |