Visual inspection equipment for wafer chips (after dicing)

Features

- This equipment performs visual inspection of chips after wafer-dicing.

- Image resolution can be selected according to inspection precision level. (Approx. 0.8 –2.0 μm/pixel); Micro inspection (0.2–2.0 um resolution)

- Simultaneous inspection of surface and rear (optional)

- Function for rejecting non-conforming chips (optional)

- Function for marking non-conforming chips (optional)

- Function for checking all elimination errors and marking errors (optional)

- Function for ID reading and mapping data output (optional)

- Two-stage specifications for performing visual inspection and rejecting non-conforming workpieces simultaneously are also available.

Overview

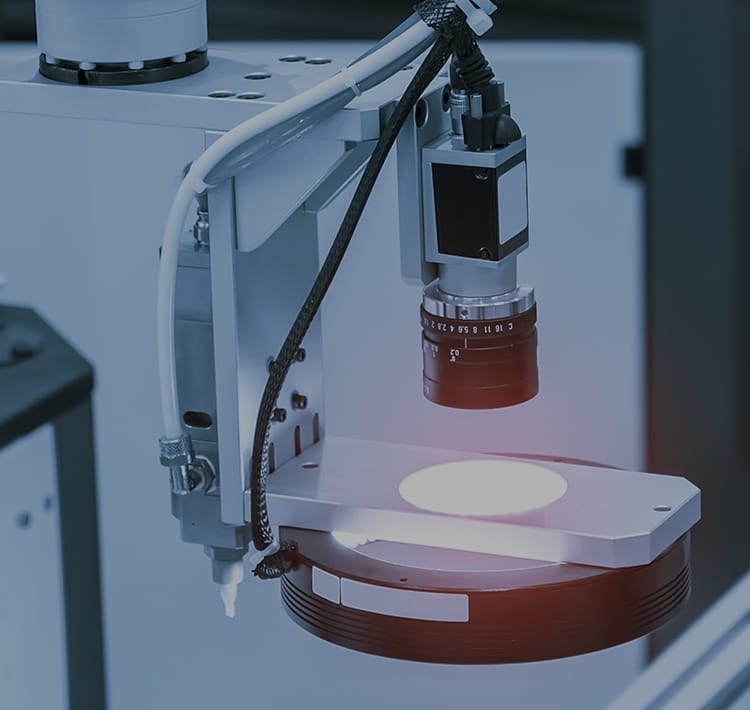

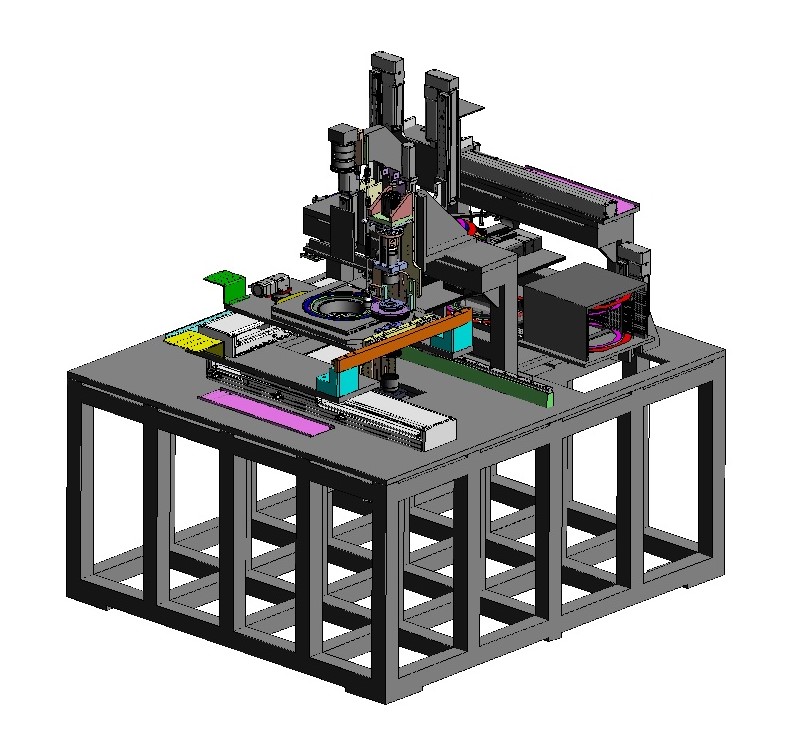

■Schematic of the equipment

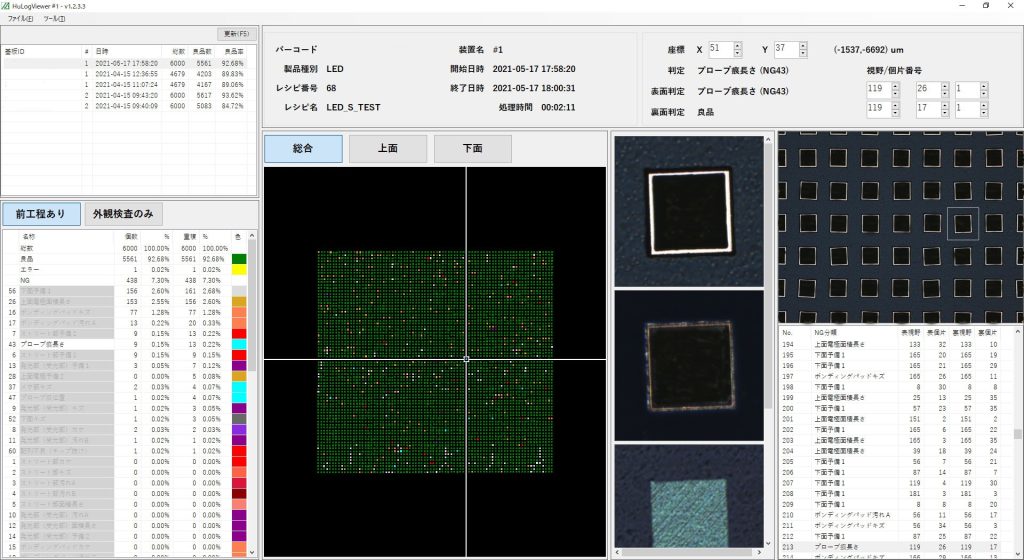

■Viewer software

- Display function for inspection results mapping

- Magnified display function for non-conforming chips

- Display function for non-conforming item classification (non-conforming items/total number of inspections/OK/Non-conforming)

■Inspection items

Dicing defects (cracks and chips), scratches, discoloration, foreign matter, pattern misapplications, pattern defects, resist residues, coating defects, etc.

■Target Products (Examples)

Various wafers types, power semiconductors, CMOS image sensors, LEDs, photodiodes

Specifications

| Software | Multifunctional image inspection software Hu-Dra |

|---|---|

| Cameras | 3.2-megapixel 3CMOS color area camera (inspection) and 16,000-pixel monochromatic line camera (pre-scan) |

| Equipment size | 1,450 (W) x 1,640 (D) x 1,800 (H) mm (excluding rotating warning light and HEPA) |

| Processing capacity | Visual inspection time: Approx. 2 minutes at 1.5 µm resolution (2 inches; chip size approx. 1 mm), Elimination time: 3–6 chips/sec (varies depending on chip size and sheet type), Marking time: 3–4 chips/sec when using inker |

| Others | Lenses and lighting may be selected based on the workpiece and inspection contents. |