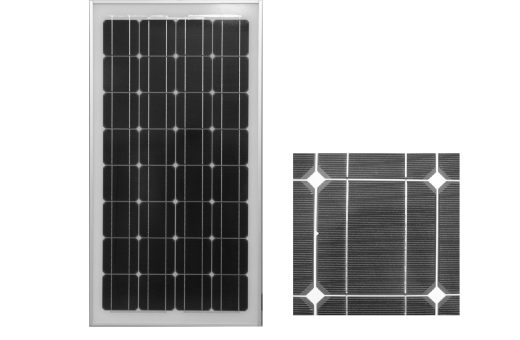

Visual inspection system for solar cells

Features

- Inspection is performed at a high level of precision for "misalignment in output lines," "cell pitch distance," "chips and cracks in cells," and the like.

- We can provide consultations on all kinds of visual inspection processes for module manufacturing processes, such as inspections of glass for modules and detection of air bubbles after resin encapsulation.

- High-pixel 2D cameras and line sensors may be selected and used according to the application.

- Since our inspection software is developed in-house, we can quickly respond to any additions or modifications requested after delivery.

- The image processing unit and transportation components are manufactured in our own factory, allowing us to respond flexibly to customers' requirements.

- Please contact us to inquire about inspection equipment for in-line and off-line inspections, etc.

Overview

■Functions

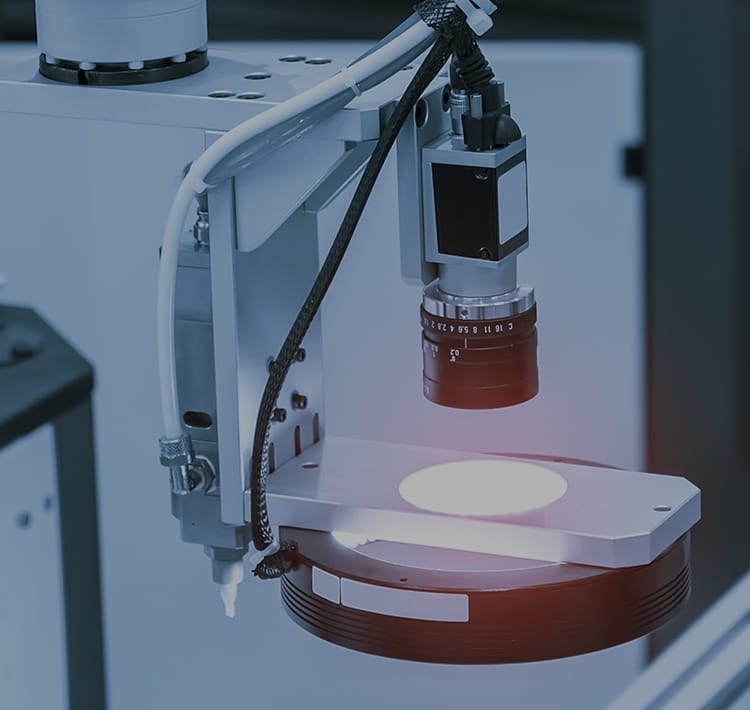

・This equipment takes images of PV modules using a high-pixel line sensor camera, detects non-conforming products, and generates signals indicating non-conforming items.

・As our image processing software is developed in-house from the basic logic stage onward, inspections can be tailored to customers’ needs.

■Inspection items

Cracked cells, chipped cells, scratches on frames, adhesion of foreign matter, tab misalignment, air bubbles, etc.

■Inspection capacity

Image processing time: 10 sec/module (depending on specifications)

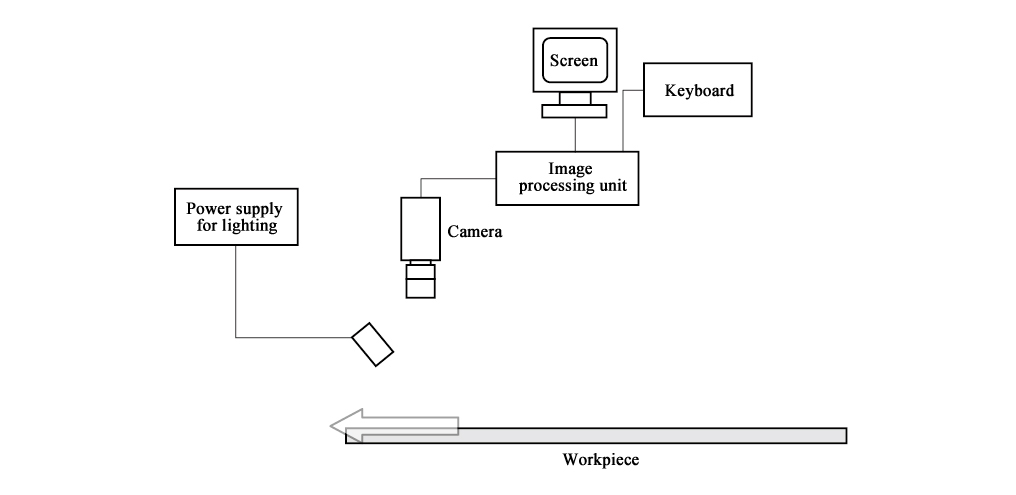

■System Configuration Diagram

Specifications

| Software | Multifunctional image inspection software Hu-Dra |

|---|---|

| Cameras | 25-megapixel color area camera |

| Power source | AC100 V ± 10% 50/60 Hz 0.5 kVA (1 unit) |