Search by industry

Search by inspection contents

Search by keywords

-

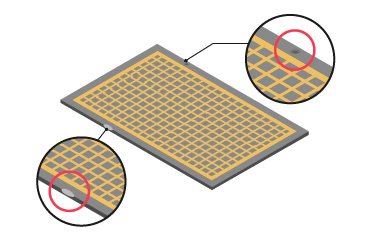

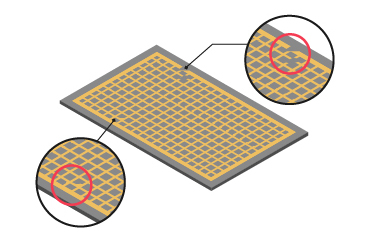

Visual inspection of circuit boards

Inspection of circuit boards for chips, unevenness, blurred and chipped patterns

- Type of industry

- Electronic components

- Inspection contents

- Surface and rear side inspection

- Product name

- Visual inspection equipment for trays High-performance tabletop visual inspection equipment Hu-cube

-

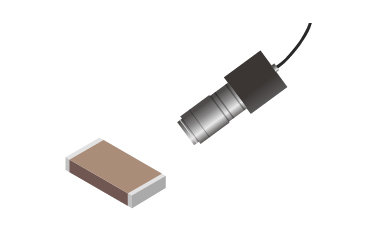

Inspection from multiple directions

Capable of 6-sided inspection including surfaces, rear sides, and 4 sides of chip components, etc.

Various types of inspection equipment are available, depending on the transportation method.- Type of industry

- Electronic components

- Inspection contents

- Multifaceted inspection

- Product name

- RMH-equipped loose-to-tray and visual inspection equipment 6-sided visual inspection equipment for electronic components Visual inspection equipment for communication/high-frequency components and device modules Inspection equipment for high-speed inspection of entire surface of cylindrical components Inspection equipment for cutting tools

-

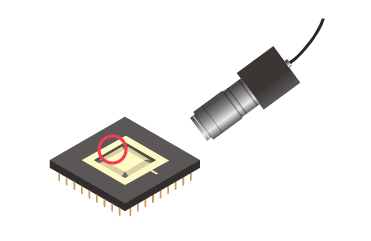

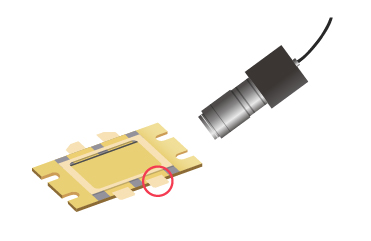

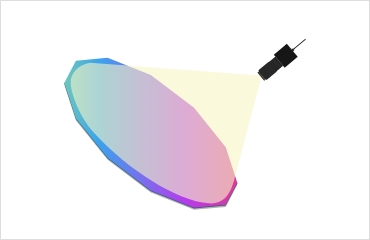

Angled inspection

Capable of inspecting IC packages from various angles, including wall surfaces and connecting parts.

- Type of industry

- Electronic components

- Inspection contents

- Deformity inspection

- Product name

- RMH-equipped loose-to-tray and visual inspection equipment 6-sided visual inspection equipment for electronic components Visual inspection equipment for communication/high-frequency components and device modules Inspection equipment for high-speed inspection of entire surface of cylindrical components

-

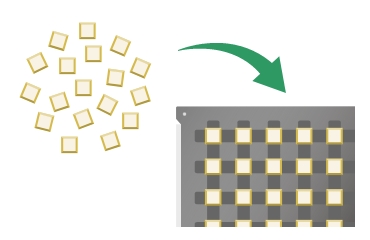

High-speed transfer and alignment of extremely small components

The suction head picks up loose components and transfers them at high speed while aligning them on the tray.

- Type of industry

- Electronic components

- Inspection contents

- Deformity inspection

- Product name

- Rotary module head (RMH)-equipped high-speed component transfer equipment

-

Counting of extremely small components

Til now, shipping quantities for metals and electronic components have been determined by conversion to mass, but due to the trend toward extremely small products, there has been an increase in counting errors.

This counting machine uses a camera which captures images of components as they flow through, separates individual workpieces through image processing, and counts the number of components, thereby improving counting precision.- Type of industry

- Electronic components

- Inspection contents

- Number counting

- Product name

- Counting Machine

-

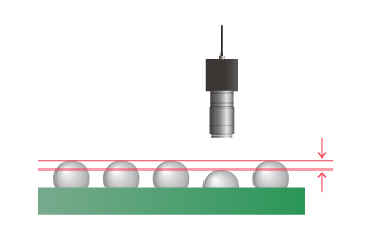

Inspection in height direction

Inspection using height information such as height abnormalities of solder bumps and dents on circuit boards

Equipped with 2D and 3D inspection function.- Type of industry

- Electronic components

- Inspection contents

- 3D inspection

- Product name

- 3D inspection system with high speed and high resolution

-

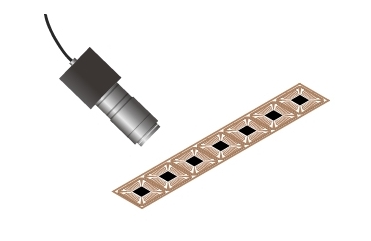

Visual inspection of lead frames

Scratches, dents, dirt contamination, etc. on lead frames are detected.

- Type of industry

- Electronic components

- Inspection contents

- Surface inspectionSurface and rear side inspection

-

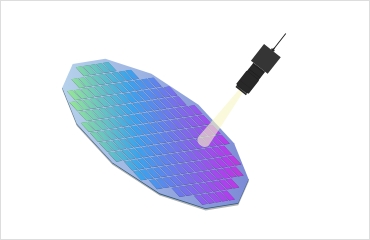

Visual inspection of wafers

Enables high-speed, high-precision inspection of visual defects that occur in the wafer processes and dicing processes.

- Type of industry

- Semiconductors

- Inspection contents

- High-precision inspectionHigh-speed inspection

- Product name

- Visual inspection equipment for wafer chips (after dicing) Visual inspection equipment for wafers (before dicing)